INDIGO DYEING : Questions & Answers

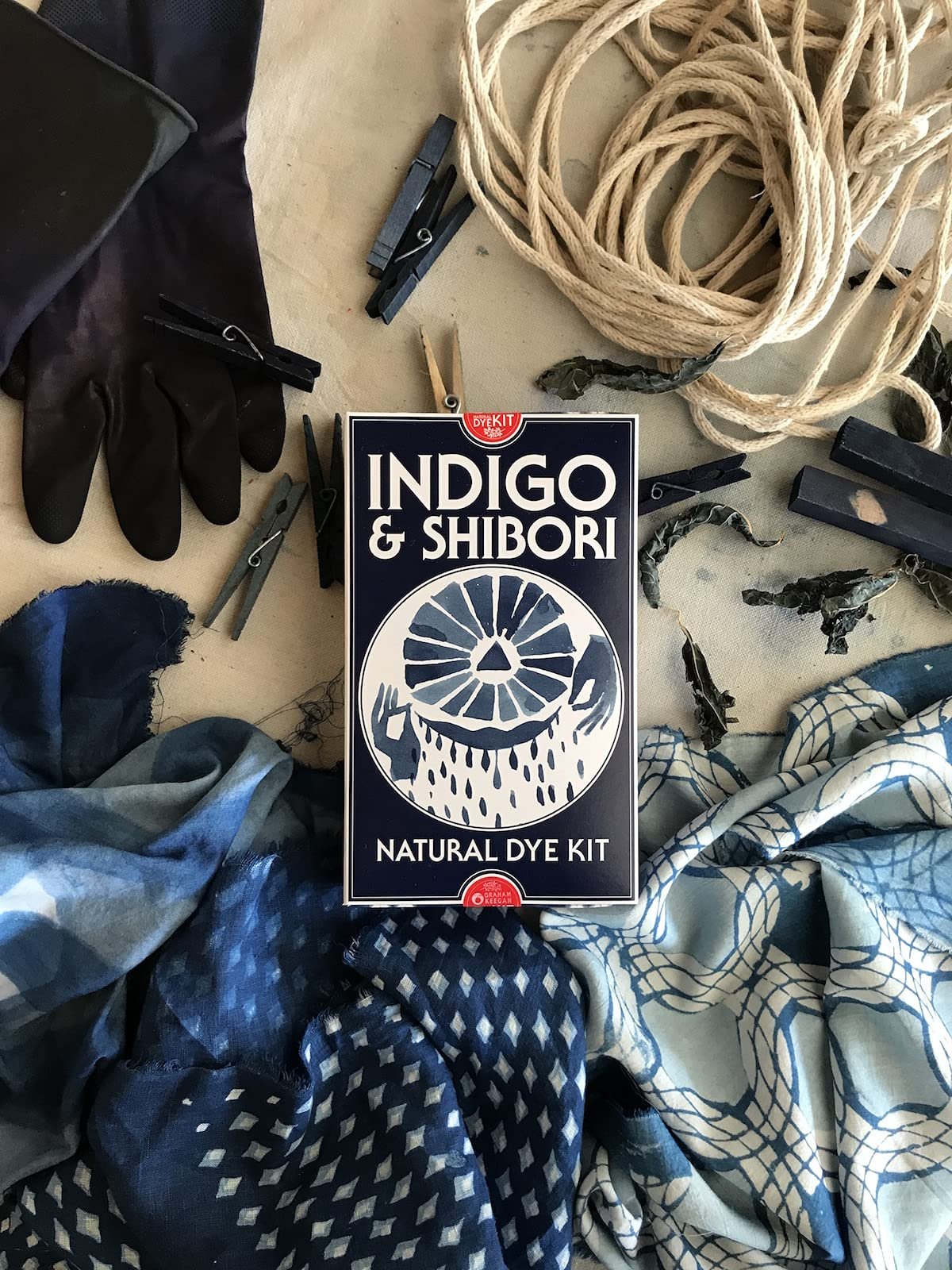

Some of the questions on this page are specific to indigo dyeing using our Indigo & Shibori Natural Dye Kit, but many are applicable to indigo dyeing more broadly!

Your dye kit comes complete with a load of supplies and materials that you can use to make designs on fabrics. Some parts of the process are complex and we may not have had room in the printed instructions included to go in depth.

If you have a question that has not yet been answered to your satisfaction, ask away!

USE KEYWORDS TO SEARCH FOR ANSWERS TO YOUR QUESTIONS

The following is an index list of each Question and Answer title, click on the title to read the corresponding Q&A, or simply use search terms in the search box above to see if your question has been answered!

-

DIP TECHNIQUE

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Dipping Resist Pieces

- Jul 26, 2023 Maintaining Your Whites While Rinsing

- Jul 25, 2023 Dyeing Over Multiple Days

- Jul 25, 2023 Avoiding Sediment

- Jul 25, 2023 How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Tips for Getting the Darkest Blues

- Jul 25, 2023 Suggestions for Uneven Coloration

- Jul 25, 2023 Rinsing Stencil Print Between Dips

- Jul 25, 2023 Number of Dips for Different Shades of Indigo

- Jul 20, 2023 Avoiding Sediment in the Ferrous Indigo Vat

-

DYE GARDEN QUESTIONS

- Jul 26, 2023 Starting Indigo Seeds Indoors Versus Outdoors

- Jul 25, 2023 When to Plant Indigo Seeds

- Jul 25, 2023 Indigo Seed Propagation

-

GENERAL INDIGO DYEING QUESTIONS

- Jul 26, 2023 Calculating Amount of Indigo Needed

- Jul 25, 2023 Dyeing Protein Fibers in a Natural Indigo Vat

- Jul 25, 2023 Dyeing Stretch Fabric with Natural Indigo

- Jul 25, 2023 Ferrous Vat Longevity

- Jul 25, 2023 Shelf Life of Natural Indigo and “Pasting-Up” Your Powder

- Jul 25, 2023 Toxicity of Indigo and Indigo Dyeing

- Jul 25, 2023 Indigo and Splatter Dyeing

- Jul 25, 2023 Indigo and Cotton Velveteen

- Jul 25, 2023 Indigo and Polyester

- Jul 25, 2023 Over-dyeing with Indigo

- Jul 25, 2023 Is Indigo Dye Okay for Sensitive Skin, Is it Safe Enough to use on Baby Clothes?

- Jul 25, 2023 Light and Pale Shades of Indigo

- Jul 25, 2023 Fixing Indigo Onto Fabric

- Jul 25, 2023 Materials and Fabrics Suitable for Indigo Dyeing

- Jul 25, 2023 Disposing of a Ferrous Indigo Vat

- Jul 25, 2023 Large Container e.g. Trash Can Vat

- Jul 20, 2023 Dye Vat Capacity

-

INDIGO LEAF EXTRACTION

- Jul 25, 2023 Making a Ferrous Vat with Fresh Indigo Leaves

- Jul 25, 2023 Clarification on Indigo Extraction

-

INDIGO VAT TIPS & TROUBLESHOOTING

- Jul 26, 2023 Is the Fermentation Vat the Best Vat?

- Jul 26, 2023 Indigo Vat Troubleshooting: No Longer an Odor

- Jul 26, 2023 Indigo Vat Troubleshooting: Dark Blue Vat

- Jul 26, 2023 Indigo Vat Troubleshooting: Greenish Tint

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Waiting 24 Hours Between Mixing and Using Your Indigo Vat

- Jul 26, 2023 Quantity of Indigo Paste in a Vat

- Jul 26, 2023 Making a Long Term Vat

- Jul 25, 2023 Indigo Flower Comes and Goes

- Jul 25, 2023 Using Pencil to Make Marks on Fabric - Does Graphite Affect the Vat?

- Jul 25, 2023 Under-Reduced Fructose Vat

- Jul 25, 2023 Troubleshooting a Different Vat Recipe

- Jul 25, 2023 Avoiding Sediment

- Jul 25, 2023 Indigo Vat Troubleshooting: Recipe Quantities for a Large Vat

- Jul 25, 2023 Sharpening Your Vat

- Jul 25, 2023 Stirring Your Vat

- Jul 25, 2023 Adding More Pigment to a Fresh Leaf Extraction Vat

- Jul 25, 2023 Making a Vat for Pale Dyeing

- Jul 25, 2023 Sizing Up Your Vat

- Jul 25, 2023 Indigo Vat Troubleshooting: Lye and Hydrosulfite

- Jul 25, 2023 Recipe for Pickling Lime and Fructose Vat

- Jul 25, 2023 Thoughts on Using Soda Ash and Spectralite Instead of Iron and Lime in Making a Dye Vat

- Jul 25, 2023 Giving Your Vat Enough Time to Set Up

- Jul 25, 2023 Switching Reducing Agent and pH Combo When Sharpening Your Vat

- Jul 25, 2023 Vat Temperature

- Jul 25, 2023 Precision of pH for Ferrous and Fructose Vats and Indicators of Under or Over Reduction

- Jul 25, 2023 Forms of Indigo that Work in a Ferrous Vat Recipe

- Jul 25, 2023 Indigo Vat Troubleshooting: Sludge and Sediment

- Jul 25, 2023 Indigo Vat Diagnosis: Vat Color, Flower, and pH

- Jul 25, 2023 Iron Vat Temperature

- Jul 25, 2023 Dissolving Lime in an Indigo Vat

- Jul 25, 2023 Reviving a spoiled or 'oxidized' indigo dye vat

- Jul 25, 2023 Mixing and Combining New Vat Ingredients with Old or Spent Vats

- Jul 25, 2023 Indigo Vat Mixing Temperature

- Jul 25, 2023 Weak Vat, Old Vat and Vat Health Restoration

-

PRE AND POST-DYE TREATMENTS & TIPS

- Jul 26, 2023 Preventing Crocking and Dyeing Large Fabrics Like Bedding

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Rinsing in Still Versus Running Water

- Jul 25, 2023 How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

- Jul 25, 2023 Troubleshooting Strange Fading Patterns and Discoloration

- Jul 25, 2023 Suggestions for Uneven Coloration

- Jul 25, 2023 Fabric Drying Stiff and Crispy Post-Dyeing

- Jul 25, 2023 Indigo Post-Dye Rinse: Purposes and Options

- Jul 25, 2023 Protecting Your Indigo-Dyed Pieces From Fading: Proper Scouring and Soy Milk Treatment

- Jul 25, 2023 Sun Fading of Indigo

- Jul 20, 2023 Best Way to Dry Indigo Dye

-

QUESTIONS ABOUT OUR INDIGO & SHIBORI DYE KIT

- Jul 26, 2023 Waiting 24 Hours Between Mixing and Using Your Indigo Vat

- Jul 25, 2023 Scaling Down Vat Size

- Jul 25, 2023 How Much Fabric Will the Natural Indigo & Shibori Dye Kit Dye?

- Jul 25, 2023 Ferrous Vat Longevity

- Jul 25, 2023 Components in the Natural Indigo & Shibori Dye Kit

- Jul 25, 2023 Indigo Form in the Natural Dye Kit

- Jul 25, 2023 Indigo Kit and Dyeing Large Items

- Jul 25, 2023 Light and Pale Shades of Indigo

- Jul 25, 2023 Scent of Natural Indigo

- Jul 20, 2023 Dye Vat Capacity

-

RICE PASTE

- Jul 26, 2023 Dipping Resist Pieces

- Jul 26, 2023 Pastry Cones for Applying Rice Paste Resist

- Jul 26, 2023 Indigo Resist Screen Printing

- Jul 26, 2023 Rice Paste Resist Longevity

- Jul 26, 2023 Destabilized AKA De-Fatted Bran in Rice Paste Resist

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Rinsing Stencil Print Between Dips

-

TIPS FOR VARIOUS DYE PROJECTS

- Jul 26, 2023 Preventing Crocking and Dyeing Large Fabrics Like Bedding

- Jul 26, 2023 Using Fresh Goldenrod Leaves to Make a Paintable Dye Pigment

- Jul 26, 2023 Type of Wood for Making Block Prints

- Jul 26, 2023 Mordant Recipe: Block vs Screen Printing

- Jul 26, 2023 Making a Stamp Pad

- Jul 26, 2023 Dyeing with Fresh Plants

- Jul 26, 2023 Indigo Resist Screen Printing

- Jul 26, 2023 Destabilized AKA De-Fatted Bran in Rice Paste Resist

- Jul 25, 2023 Dipping Metal in my Vat

- Jul 25, 2023 Using Natural Indigo Paste

- Jul 25, 2023 Dyeing Vegetable Tanned Leather

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Dyeing Paper

- Jul 25, 2023 Chalk and Cheesecloth Clarification in Mordant and Block Printing

-

USING MORDANTS

- Jul 26, 2023 Mixing Mordant

- Jul 26, 2023 Mordant Recipe: Block vs Screen Printing

- Jul 26, 2023 Diluting Mordant Paste

- Jul 25, 2023 Chalk and Cheesecloth Clarification in Mordant and Block Printing

Preventing Crocking and Dyeing Large Fabrics Like Bedding

Q: How do I prevent indigo dye from rubbing off onto other surfaces when the fabric is subjected to abrasion? My daughter dyed some bedding with a very similar kit and over time it left blue in our dryer and stained some other bedding/clothing.

A: Great question! Also, the tendency of a dyed fabric to give off color when the surface is rubbed is called crocking. Bedding is notoriously challenging to dye well in home use kits! Every sheet or duvet cover or whatever is just so much material that it often overwhelms the activity of the vat and causes the vat chemistry to become oxidized and the indigo becomes under-reduced which causes poor color uptake into the fabric. This leads to more crocking of your goods.

Also, large items will inevitably stir up whatever sediment exists at the bottom of the vat which can also 'clog' (for lack of a better term) the fabric which will also lead to poor and uneven color uptake.

I mostly dye indigo in a 50 gallon vat - and that can handle sheets and larger yardage panels but even I don't dye them often! Sheets are a great place to practice some larger folded patterns though. And they're much easier to dye when folded into bundles. I recommend keeping the total number of layers of the material under 25 otherwise you just end up with a LOT of white area.

My recommendation for optimizing color uptake on large items and avoiding crocking would be to pre-soak the goods in hot water prior to going in the vat with the addition of a little soda ash - say a tablespoon per gallon. This alkaline water can really help wet out the fabric and will help keep the pH of the vat from shifting toward acidic.

Other than that, rinse rinse rinse prior to washing after dyeing. And I always wash indigo goods alone on their first laundering. Also I never wash in a front loading washer with the tight seals. Those can actually create and maintain a reduction environment which can discharge some color from the piece during the cycle. I wash all my indigo goods in a top loader on the gentle setting with detergent.

There are also soy coatings made from fresh bean soy milk that can be added onto fabric after dyeing to essentially seal in the indigo but those require ageing and oxidizing (for at least a few weeks) before washing. They act as a transparent protective later. I hope to post more about that soon. John Marshall covers that process in his book Singing the Blues - shameless plug - which is available on my website www.grahamkeegan.com

Avoiding Fading

Q: I dyed several pieces in a ferrous vat and had great results. They came out with great deep blues. However, they have faded terribly since then. Any idea what I might be doing wrong?

A: The typical culprits on fading are:

Choice of material being dyed. Some materials have received inadequate preparation and have some sort of coating remaining on the fiber itself which keeps the indigo from dyeing directly to the cellulose. Well scoured materials will dye more evenly and will hold up to all kinds of wear (UV, Washing). Some fibers also just dye more easily. For example rayon is super easy to dye and linen is more challenging.

Conditions in the vat may have been under-reduced, meaning that the indigo was not in proper shape to adhere to the fabric.

Sediment layering. If your fabric hits the sediment on an early dip, future dips will adhere to the gunk layer you picked up from the sediment and then wash out later as the sediment itself eventually breaks down and moves along.

Rinsing in Still Versus Running Water

Q: I have a question about rinsing my pieces after dyeing. Does it have to be done in running water or can it be done in multiple buckets?

A: The rinsing can be done in dingy water up until the moment the piece is going to be opened. At that point, use fresh water (or at least the cleanest rinse water bucket you have). Dirty rinse water can stain the pristine white resisted portions of the fabric. The staining is not permanent but it is difficult to remove and will naturally fade out over time (though in patchy ways and will turn yellow before disappearing).

How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

Q: I am dyeing in a ferrous vat and got sediment from the bottom of the vat on my piece. Is that bad? What should I do?

A: A ferrous vat has an iron-rich sediment which collects at the bottom of the vat. If you’ve gotten any of this sediment on your piece make sure you rinse it thoroughly in fresh flowing water before it goes back into the vat for its next dip. If the sediment is resting on your piece when you dip into the vat the indigo pigment will adhere to the sediment and not the fabric. It functions like a resist on the fabric and when you finally wash the piece, you’ll rinse all of the indigo off back to the dip where the piece first hit the sediment. You can’t over-rinse between dips!

Contact with the sediment can also stain your pieces with a mottled brown/green. To remove the staining, wash the pieces with excess detergent in hot water (bar soap works great) until the water rinses clean.

The deeper your vat container is the easier it is to avoid the sediment. If you need to dye in a small vat but have pieces that are large in size you can try putting some sort of bag/basket/strainer in the vat secured to the top of the container so that your pieces literally cannot touch the sediment. Also, make sure to not stir the vat beforehand on the same day it is used to dye so that the sediment has time to settle.

Troubleshooting Strange Fading Patterns and Discoloration

Q: Some of my indigo-dyed pieces have developed yellowish haloes around what used to be light blue (dry already for weeks) and one developed a random yellowish streak where I would guess it had been exposed to direct sunlight? Any idea why this is happening or what I can do to get better results next time?

A: This type of fading/discoloring sounds to me like classic not-properly-scoured results. To properly scour your fabric prior to dyeing boil it in soda ash for at least 4 hours, then rinse thoroughly. Cotton (and other natural cellulose fibers) are often sheathed in waxes and pectins which are not ideal bonding sites for indigo because they can (and eventually will) separate from the cellulose fibers themselves, taking any indigo attached to them. Properly scoured fabric is free of these compounds and you’ll find that those fabrics dye more easily, evenly and the colors hold up best.

Also, did you properly wash and pH balance your pieces after removing them from the dye vat? If you leave them as is (without an acidic rinse) they have a tendency to fade as you’ve described when exposed to sun and humidity. If you are using my dye kit, be sure to use the provided Citric Acid as described in the instructions. If not, adding a half cup of vinegar to all the pieces in a load of laundry is strong enough to get them pH balanced.

Suggestions for Uneven Coloration

Q: I am getting uneven color when I am dyeing. Any suggestions?

A: Uneven coloration can be a result of many different factors. Not thoroughly scouring your fabric before dyeing can lead to uneven results. As can not agitating / moving your fabric while it is in the dye vat to ensure the liquid covers all parts of the piece equally. Also, if sediment from the bottom of the vat gets on the piece, it can block future dips in the vat from effectively transferring pigment to the piece. Just make sure to thoroughly rinse between dips to avoid this.

Fabric Drying Stiff and Crispy Post-Dyeing

Q: Sometimes my fabric feels really stiff and crispy after I dye it. Any suggestions?

A: I would make sure you are rinsing your pieces really well after dyeing them and rebalancing the pH of your fabric in a post-dye acid bath (citric acid, lemon, vinegar are some suggestions) before allowing them to dry out. Not doing so can make your fabric really stiff and crispy when it dries. As a general matter, high pHs soften cellulose fibers (soda ash on cotton, hemp, linen etc) and low pHs soften protein fibers (vinegar on silk, wool).

Indigo Post-Dye Rinse: Purposes and Options

Q: Your kit uses citric acid as a post-dye-rinse. Why is this necessary and can I use something different as a post-dye-rinse?

A: Dipping your fabric in a citric acid bath after dyeing rebalances the pH of your fabric and sets the indigo pigment. For an indigo post-dye rinse, any acidic household product will work: lemons and vinegar are two easy ones. Simply add some to water and submerge your piece and agitate for a few minutes. Then follow with a water rinse and a laundering.

For vinegar, you can use approximately half a cup per one gallon of water. For lemons I recommend one squeezed whole lemon per gallon of water.

Protecting Your Indigo-Dyed Pieces From Fading: Proper Scouring and Soy Milk Treatment

Q: Are there ways to protect my indigo-dyed fabrics from fading? It seems like some of my indigo-dyed fabrics have faded from being dried in the sun - is that possible?

I've heard that soy can be used to help fix the indigo pigment. Can you let me know how to do this?

A: Fading can happen on indigo dyed pieces for a number of reasons: incomplete or insufficient scouring of fabric prior to dyeing, under-reduced vat conditions resulting in weakly adhered dye to fiber, ultraviolet light as well as ozone exposure. As a general matter, if you are drying your pieces outside keep them in the shade whenever possible. Indigo is very susceptible to fading when it is exposed to UV light while wet.

For long lasting blues, first, make sure your fabric is totally scoured prior to dyeing : boil it in soda ash for at least 4 hours, then rinse thoroughly. Cotton (and other natural cellulose fibers) are often sheathed in waxes and pectins which are not ideal bonding sites for indigo because they can (and eventually will) separate from the cellulose fibers themselves, taking any indigo attached to them. Properly scoured fabric is free of these compounds and you’ll find that those fabrics dye more easily, evenly and the colors hold up best.

And yes, soy milk treatments can add a layer of protection against crocking (fading from rubbing) and UV exposure by (to my knowledge) adding a protein “glazing” to the piece.

When I do soy milk treatments, I make the soy milk from scratch. I soak the beans for 24 hours, blend in the excess water, strain off the solids, and use the liquid. I suggest making your own soy milk as well. Purchased soy milk has gone through a number of processes to make it shelf stable and it contains other ingredients. I don’t have enough experience to say for sure that purchased soy milk would not work as well as homemade soy milk, but I do know that it smells and feels different than fresh soy milk.

To treat your piece, dip it into the milk to wet it and then wring the piece out and allow it to dry flat. You will want to rotate the piece periodically as it dries otherwise the fabric has a tendency to stick to whatever surface it is on.

Sun Fading of Indigo

Q: Will sun fade the indigo? I noticed my indigo was a lot darker when I first placed it on the line to dry.

A: Yes, sun will naturally fade indigo. However, it takes days, weeks and months of UV exposure to remove substantial amounts of color. It sounds like you're describing the process of lightening that naturally happens when the piece dries out. Wet indigo dyed textiles always appears darker than the same fabric when dry. I recommend two or three more dips in the indigo vat AFTER you see the fabric reach the shade that you want.

Re: actual sun fading of indigo dyed textiles : In John Marshall’s book Singing The Blues (which I highly recommend as a practical guide to working with indigo), he published photos of fabrics that have been exposed to comparable amounts of sunlight. One piece of fabric had been treated with a soy-milk after bath, the other received no such treatment. The fabric which received a layer of soy milk following dyeing was appreciably better at resisting the UV fading effects of the sun. I’m now firmly in support of dipping all my own indigo dyed textiles in a solution of soy milk (I’ll make my own from whole soy beans if I have the time, but will also use pure, no-sugar-or-flavor-added bottled soymilk) after their pH balancing rinse and allowing the soy to dry on the fabric. I won’t wash the item for a month to allow the soy to properly cure onto the fabric.

Best Way to Dry Indigo Dye

Q: What is the best way to dry indigo dyed fabric? Should I avoid drying it in the sun?

A: Yes, dry in the shade. Indigo is very susceptible to fading when it is exposed to UV light while wet.