INDIGO DYEING : Questions & Answers

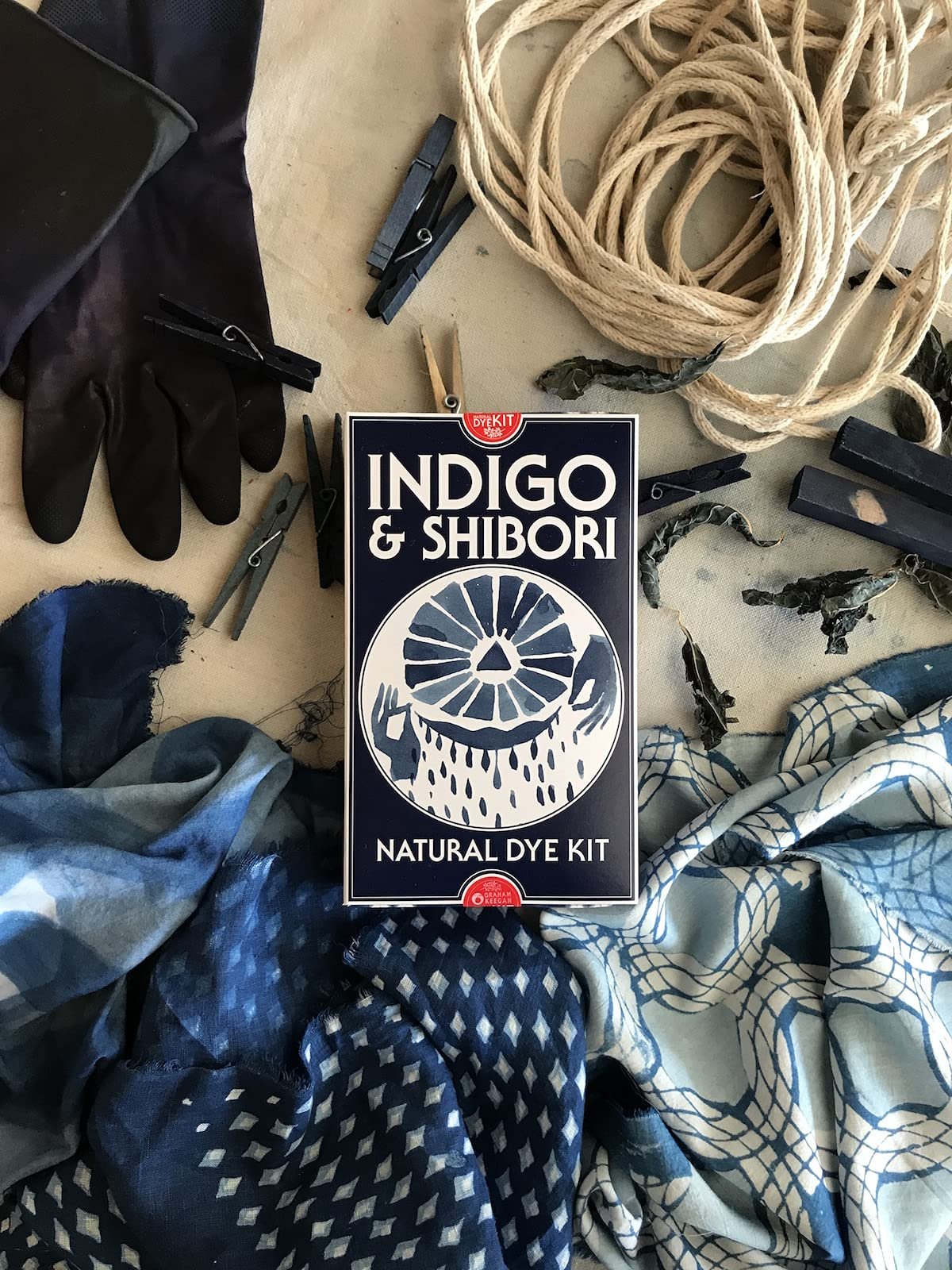

Some of the questions on this page are specific to indigo dyeing using our Indigo & Shibori Natural Dye Kit, but many are applicable to indigo dyeing more broadly!

Your dye kit comes complete with a load of supplies and materials that you can use to make designs on fabrics. Some parts of the process are complex and we may not have had room in the printed instructions included to go in depth.

If you have a question that has not yet been answered to your satisfaction, ask away!

USE KEYWORDS TO SEARCH FOR ANSWERS TO YOUR QUESTIONS

The following is an index list of each Question and Answer title, click on the title to read the corresponding Q&A, or simply use search terms in the search box above to see if your question has been answered!

Avoiding Fading

Q: I dyed several pieces in a ferrous vat and had great results. They came out with great deep blues. However, they have faded terribly since then. Any idea what I might be doing wrong?

A: The typical culprits on fading are:

Choice of material being dyed. Some materials have received inadequate preparation and have some sort of coating remaining on the fiber itself which keeps the indigo from dyeing directly to the cellulose. Well scoured materials will dye more evenly and will hold up to all kinds of wear (UV, Washing). Some fibers also just dye more easily. For example rayon is super easy to dye and linen is more challenging.

Conditions in the vat may have been under-reduced, meaning that the indigo was not in proper shape to adhere to the fabric.

Sediment layering. If your fabric hits the sediment on an early dip, future dips will adhere to the gunk layer you picked up from the sediment and then wash out later as the sediment itself eventually breaks down and moves along.

Dipping Resist Pieces

Q: Any best practices for dipping pieces with resist patterns on them?

A: Yes, here are a few:

Be very careful when dyeing and removing your pieces from the vat as any drips will begin to weaken the vat. Remove your pieces very slowly and that will minimize.

Make sure you soak your goods in cold water with a drop or two of synthropol (which helps with dye penetration) so they are nice and saturated before they go in the vat. This will allow for even dye uptake.

If you are using wax resist make sure your vat is cool enough so the wax won’t melt when you dip.

Make your vat in as tall and skinny of a container as possible so you can fully submerge your piece without it getting in the sediment.

Set your pieces onto little wire rings that fit inside your container. (i just make mine with moldable wire from the hardware store, often used for clothesline) and dip them so they never touch themselves. Always fully wet your waxed pieces in cold water with a drop or two of synthropol (which helps with dye penetration) prior to their entry into the vat. Here's a video of an impromptu ring that I made. https://www.instagram.com/p/BKq390-DAC1/?taken-by=yesgraham

Maintaining Your Whites While Rinsing

Q: I am using an indigo vat but I find in the rinsing process the whites become tainted by the blue. Any suggestions on how to keep the whites white? Also any tips for washing in the machine and maintaining the whites?

A: I have four quick tips for you:

1. Rinse your pieces in fresh water (maybe add a lil dish soap and wash by hand) BEFORE opening (untieing or unclamping).

2. Rinse in COLD water literally AS you open the piece, gradually raising the temperature when the water rinses clear.

3. pH balance the work after first rinse by submerging into water with slight acidity (added vinegar, lemon juice, citric acid powder, black tea, etc).

4. Use washing machine on cold with mild soap the first time around. If it is a top loader, let it fill with water before the dyed goods go in. If it is a top or front loader use the maximum size load setting possible even if you are only washing a couple pieces. The excess rinse water helps keep the background clear.

Dyeing Over Multiple Days

Q: I have done several dips on a piece that I have shibori tied. I would like to do more dips, but need to stop for the day. Can I stop mid-process on a piece, let it dry, and come back to it tomorrow or in a week?

A: Yes, no problem. Just be sure to rinse your piece VERY well before it dries and fully re-hydrate it before the next round of dyeing.

Avoiding Sediment

Q: I made a 5 gallon iron vat following the instructions on your website and I am trying to dye some cotton gauze scarves. The first one came out well but the rest have come out a grey/green - any thoughts on what I might be doing wrong? I am wondering if I am coming into contact with the sediment at the bottom of the vat? The only other time I dyed I was dipping in a 55 gallon drum so I didn’t have to worry much about the sediment and I am wondering if now that I’m using a smaller vat if my pieces are dragging in the sediment. Is there a way to protect against that?

A: Yes, it does sound like sediment is the issue. The ferrous vat has an iron-rich sediment, which when coming into contact with the fabric will stain it yellowish - and when that is layered with the indigo, a sludgy green. My suggestions would be to switch to a bigger/deeper container and avoid the sediment altogether or put some sort of bag/basket/strainer in the vat secured to the top of the container so that the pieces literally cannot touch the sediment. Also, make sure to not stir the vat beforehand on the same day it is used to dye. The sediment needs time to settle.

If you are dyeing in a steel pot, I recommend heating the contents up to about 120 and holding for an hour or so, stirring occasionally. This will revitalize the vat. Otherwise, you can reheat the contents with some sort of heating element or bucket wrap like this: https://www.amazon.com/dp/B00OYEABGQ/ref=biss_dp_t_asn

It may seem "expensive" but its amazing how much better a warm vat performs!

How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

Q: I am dyeing in a ferrous vat and got sediment from the bottom of the vat on my piece. Is that bad? What should I do?

A: A ferrous vat has an iron-rich sediment which collects at the bottom of the vat. If you’ve gotten any of this sediment on your piece make sure you rinse it thoroughly in fresh flowing water before it goes back into the vat for its next dip. If the sediment is resting on your piece when you dip into the vat the indigo pigment will adhere to the sediment and not the fabric. It functions like a resist on the fabric and when you finally wash the piece, you’ll rinse all of the indigo off back to the dip where the piece first hit the sediment. You can’t over-rinse between dips!

Contact with the sediment can also stain your pieces with a mottled brown/green. To remove the staining, wash the pieces with excess detergent in hot water (bar soap works great) until the water rinses clean.

The deeper your vat container is the easier it is to avoid the sediment. If you need to dye in a small vat but have pieces that are large in size you can try putting some sort of bag/basket/strainer in the vat secured to the top of the container so that your pieces literally cannot touch the sediment. Also, make sure to not stir the vat beforehand on the same day it is used to dye so that the sediment has time to settle.

Tips for Using Rice Paste in a Ferrous Vat

Q: I am interested in making an iron vat for the first time and would like to do some stencil dyeing with rice paste. I see that you suggest rinsing the fabric after each dip but I am concerned that the rinsing will cause my rice paste to come off. Do I need to rinse between every dip? What is the purpose of rinsing?

A: I rinse between dips for a couple reasons: first, it helps to oxidize the indigo more quickly and thoroughly, second, it rinses off any sludge, sediment or flower that may be trapped on the piece or in the crevices which would act as a resist for future dips.

But you have good instinct. When stencil dyeing with rice paste, to ensure the paste does not rinse off, I generally do not rinse between dips unless my piece makes contact with the sediment at the bottom of the vat. If your piece does hit the sediment you WILL need to rinse.

Make sure you don’t crinkle/crumple your pieces to get them in the vat. Rice pasted pieces do best when dipped cleanly into the vat. Because of this, be sure to dye in a very deep vat so your fabric can hang freely in the liquid and not touch the sediment.

For dark results where you need to dip many times, stick to 2-3 dips per day so the rice paste has a chance to dry out and stay firm. I have also found that if I stick to 2-3 dips per day (only dipping once is the safest bet) I can get away with rinsing gently between dips and then giving the piece 24 hours to totally dry out before doing further dips. Rice paste stays pretty resilient as long as it does not get too hydrated which is partly why I prefer using rice paste to clay or other resists which wash off very easily. I’ve found it to be the most tenacious non-wax resist.

I should also note that while dyeing in a heated vat has superior results to dyeing in a cold vat, when dyeing rice pasted pieces a cooler temperature works better because a warm/hot vat will disintegrate the paste after a dip or two.

Tips for Getting the Darkest Blues

Q: Any tips for getting really dark blues with a natural indigo vat?

A: For a dark color, I dip my piece for at least 3 minutes per dip and THOROUGHLY rinse with cold water in between dips. You can re-dip as soon as you see no more green in the folds of the piece. There is no set time between dips, you actually just need to oxidize your indigo layers, which is indicated by the indigo turning completely blue.

Make sure to avoid hitting the sediment at the bottom of the vat. If you do, rinse and wash the material from your piece before attempting another dip, otherwise all subsequent dips in the vat will merely bond indigo to the sediment, which will eventually wash off, taking all that indigo with it.

Suggestions for Uneven Coloration

Q: I am getting uneven color when I am dyeing. Any suggestions?

A: Uneven coloration can be a result of many different factors. Not thoroughly scouring your fabric before dyeing can lead to uneven results. As can not agitating / moving your fabric while it is in the dye vat to ensure the liquid covers all parts of the piece equally. Also, if sediment from the bottom of the vat gets on the piece, it can block future dips in the vat from effectively transferring pigment to the piece. Just make sure to thoroughly rinse between dips to avoid this.

Rinsing Stencil Print Between Dips

Q: I am curious why it is necessary to rinse your fabric after each dip when using the iron vat? As I'll be doing a lot of stencil dyeing I am wondering if the rinsing will become an issue with the paste coming off.

A: I don’t typically rinse between dips with the paste dips because it will rinse off. However, if my piece hits the sediment in the ferrous vat, I DO rinse. Make sure you are dyeing in a very deep vat so that your fabric can hang freely in the liquid and not touch the sediment. For dark results, stick to 2-3 dips per day so the rice has a chance to dry out and stay firm. I rinse between dips for a couple reasons : first, it helps to oxidize the indigo more quickly and thoroughly, second, it rinses off any sludge, sediment or flower that may be trapped on the piece or in the crevices which would act as a resist for future dips.

Number of Dips for Different Shades of Indigo

Q: How many times do I have to dip to get a super dark indigo?!

A: This dip-o-meter was produced using the Indigo & Shibori Kit. As you can see, each dip adds a bit more pigment to the piece. The earlier dips were as short as 20 seconds, while the later dips lasted as long as 10 minutes.

Avoiding Sediment in the Ferrous Indigo Vat

Q: How do I protect my goods from the sediment at the bottom of my iron vat. Could you describe in more detail the ideal set-up for a basket or net that I could place in the indigo vat?

A: Yes, the sediment at the bottom of the indigo kit can bond to your piece of fabric and create what I’ll call a ‘false foundation’ upon which all future layers of indigo will bond. When finally washed out, all subsequent layers of indigo will rinse off when the sediment is eventually rinsed off.

If you get your piece into the sediment, make sure to rinse it thoroughly (you can also even use soap, scrubbing sponges or pressure from a hose to blast off the sediment) before dipping it back into the vat to layer on additional color. If the sediment contained a lot of fresh iron, it has the ability to tint your fabric yellowish/brownish where it comes in contact, even after thorough rinsing. To remove this stain, simply add a teaspoon of the citric acid powder included in the kit into a couple gallons of hot water, make sure it is dissolved and soak your pieces overnight (agitating when you remember to). Rinse your pieces until the rinse water comes clear and then resume dyeing.

To avoid all that hassle, you can get some sort of mesh bag (like an inexpensive synthetic mesh laundry sack, or even a layered piece of cheesecloth) and secure it to the rim of the vat and make sure that it only hangs about half way down the vat so that the pieces cannot go all the way to the bottom and make contact with the sediment. You can remove and rinse the bag when you replace the lid on your vat after dyeing.